Cutting

All FormEffects panels are fabricated using a glass fiber reinforced concrete (GFRC) mix that is free of any large aggregate and steel reinforcement which allows the panels to be very easily cut and drilled in the field to accommodate all kinds of conditions.

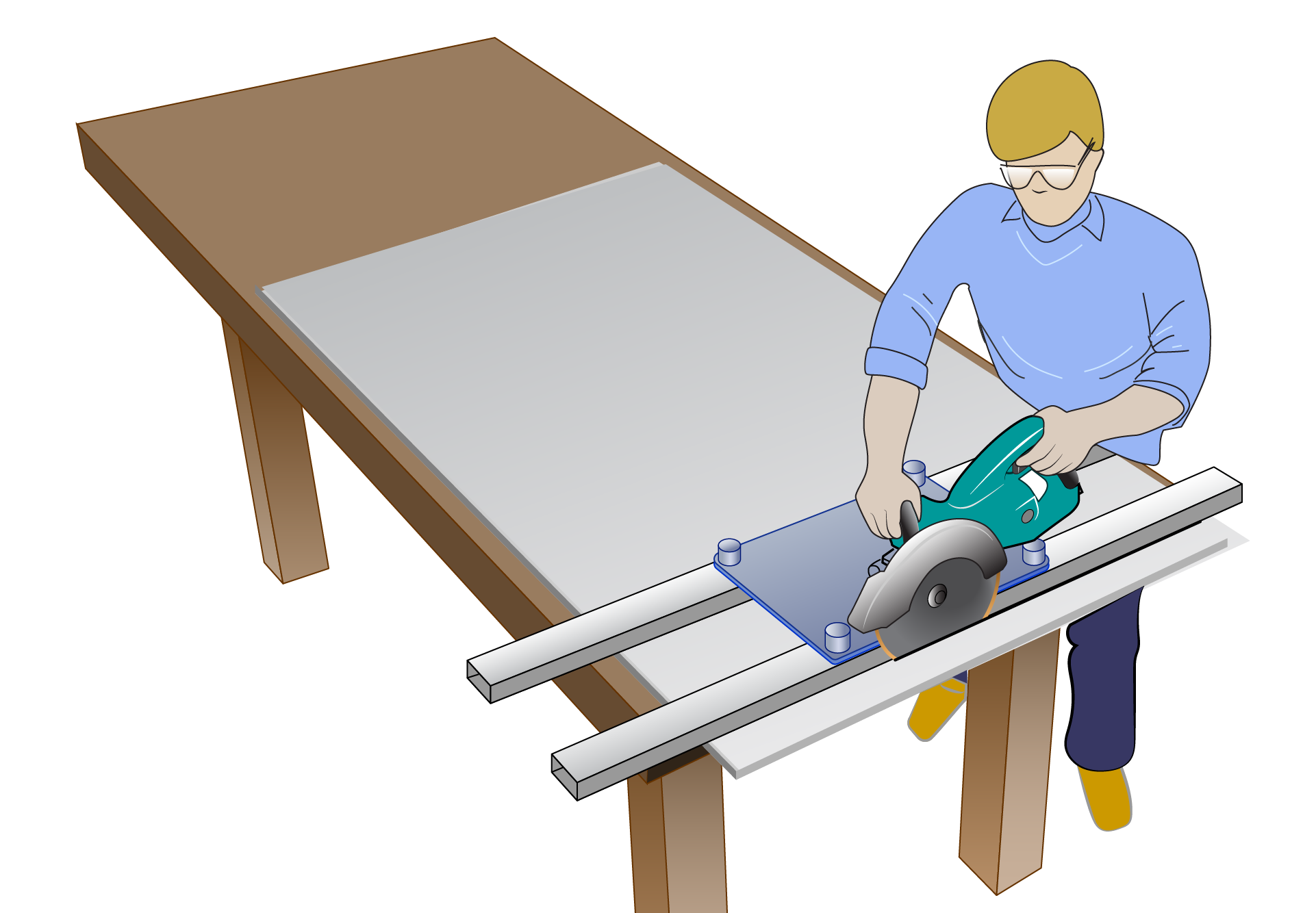

- Place the panel face up on a level cutting table. It is important to have continuous support underneath the full panel. Otherwise, use a large rigid substrate on top of saw horses to build a cutting surface.

- Mark your measurements onto your panel.

- If making a long, straight cut it would be recommended to use a guide rail clamped to the panel. Many stone rail saws, such as the Omega Blue Ripper Jr., come with guides and is a good investment for projects with an extensive amount of cuts. Ensure any tools or equipment making contact with the panel are clean and free of debris that could scuff the panel.

- Using a circular drive plunge cut saw with a continuous rim diamond blade, make the cut across the panel.

- DO NOT USE WATER OR A WATER FEED. The cuts should be made dry. The slurry that results in a wet cut will be absorbed by the fresh cut edge of the concrete panel which could use darkening.

- Use a vacuum with a soft bristle attachment to remove the dust off the surface.

- For small intricate cuts, notch outs, or to finish off a large cut you can use an angle grinder with a 4″ to 5″ continuous diamond cutting blade and make the cut freehand.

SAFETY

Operators cutting and/or drilling concrete should always take the proper safety precautions. Respiratory and eye protection should be worn. All equipment should be inspected prior to operation and the work area should be free of any potential hazards.

Tools Required:

- Cutting Table

- Circular Plunge Cut Saw

- Continuous Rim Diamond Cutting Blade (Dry)

- Guide Rail

- Vacuum

Drilling

-

- Place the precast panel or top face up on a large, flat work surface with continuous support to prevent flexing of the concrete.

- Use the grinder with the desired drill bit size to drill a hole in a piece of masonite or thin plywood to serve as a bit guide when drilling the concrete.

- Locate your desired hole locations and align your bit guide onto your location. Secure the bit guide to the surface with a clamp or safe release masking tape.

- Protect the surrounding area of the precast area or top with plastic sheeting.

- Place the bit into the bit guide prior to turning on the grinder.

- Begin drilling, applying medium pressure to the grinder, through the depth of the concrete at a slow, constant rate.

- Immediately after drilling, vacuum any dust accumulated on the surface, remove the bit guide, and gently wipe the surface with a clean, damp microfiber towel to remove any remaining concrete dust.

- Ensure when moving the panel or top off the work surface, proper handling techniques are used. The precast should be lifted and handled with the short dimension perpendicular to the ground, avoiding it being parallel to the ground as much as possible.

Tools Required:

- Angle Grinder

- Diamond Core Dry Drill Bit (in required size)

- Grinder Dust Shield or Vacuum Shroud

No products in the cart.

No products in the cart.